-

Product DescriptionCompany Info.<>

- Model:

- DN100/150

- Processing customization:

- Yes

- Material:

- stainless steel

- Use:

- Chemical, petrochemical, pharmaceutical, environmental protection

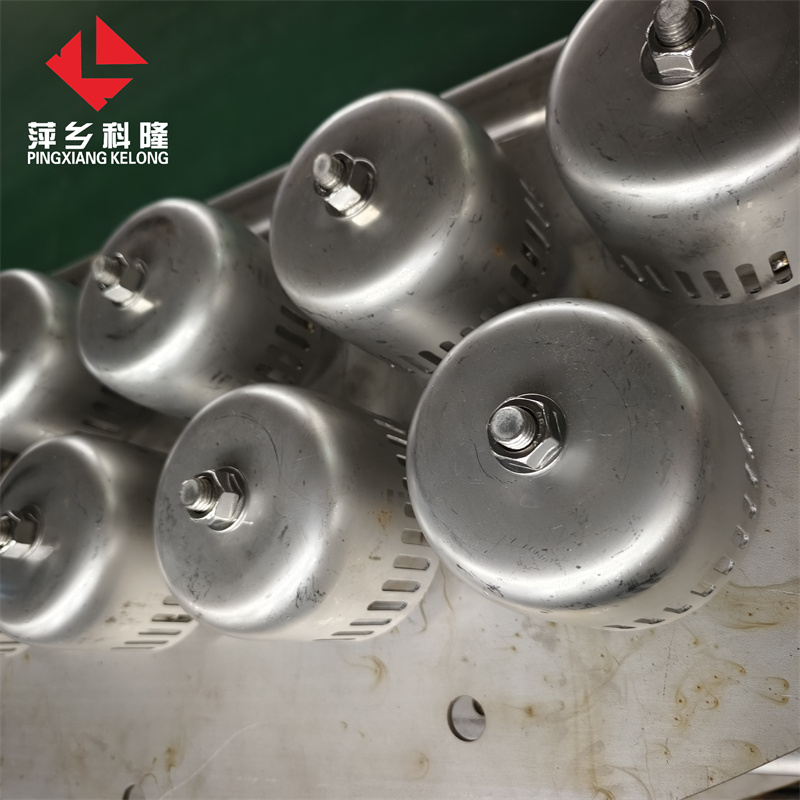

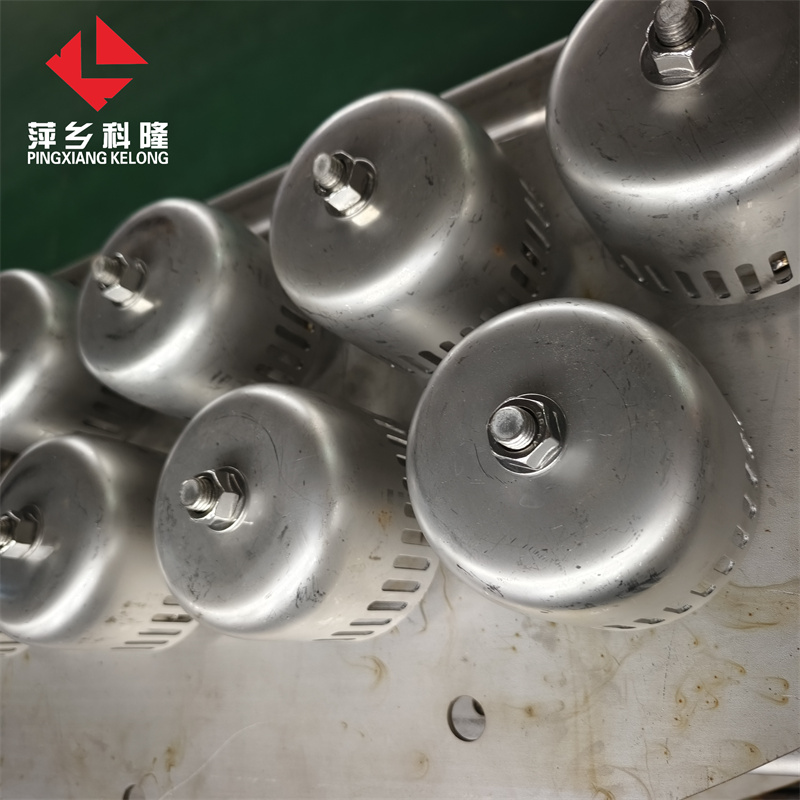

Stainless steel bubble cap is one of the main components of bubble tray, usually made of stainless steel material. Its main function is to provide a gas-liquid interface to promote heat and mass transfer between gas and liquid. In industrial production, stainless steel bubble tray is widely used in chemical, petrochemical, pharmaceutical, environmental protection and other fields, for distillation, absorption, extraction and other unit operations

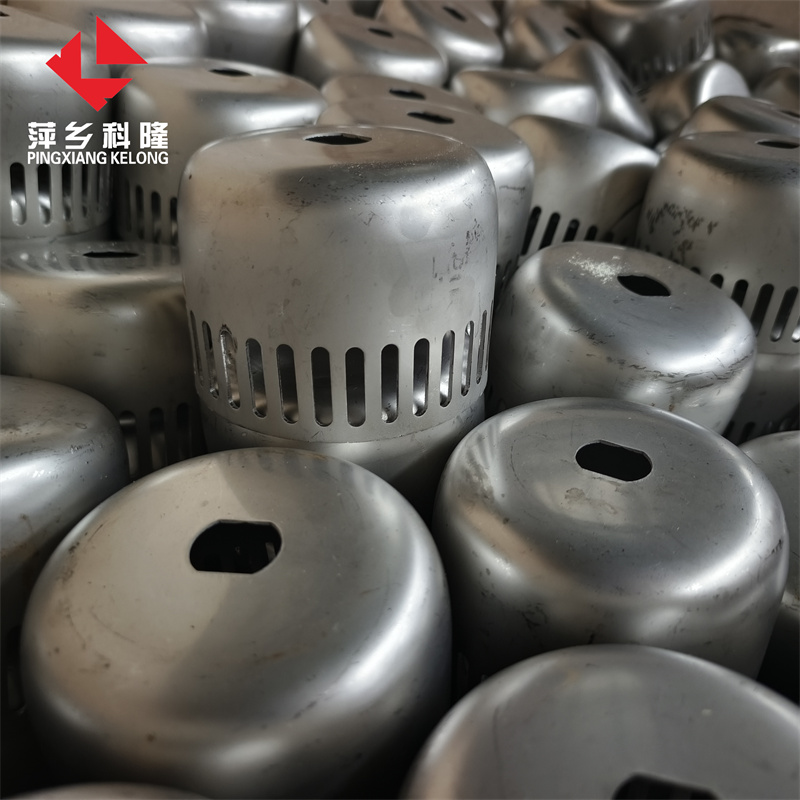

Complex structure: The bubble cap usually consists of a gas riser and the bubble cap itself. The gas riser connects the column plate and the bubble cap. There are many small holes or gaps in the bubble cap for the passage of gas and the dispersion of liquid. Flexible operation: bubble tray can maintain stable operation performance in a large range of gas-liquid flow to adapt to different production requirements. Not easy to plug: bubble cap design can reduce solid particles and impurities blocking, to ensure the normal operation of the tray. High efficiency: bubble tray provides a large gas-liquid contact area, which is conducive to heat transfer and mass transfer process and improves separation efficiency.

The width and depth of the slots also affect the bubble size and the velocity of the gas. Increasing the width and depth of the slot properly can make the bubbles bigger, but it may reduce the dispersion of bubbles; conversely, decreasing the width and depth of the slot will make the bubbles smaller, but it may increase the resistance of gas passage. Therefore, it is necessary to optimize the shape and size of the slot according to the specific process requirements and operating conditions to obtain the best gas-liquid contact effect and operating performance.

Height and diameter of riser pipe: The height of riser pipe determines the distance between the bottom of bubble cap and tray, which in turn affects the liquid sealing effect and gas flow path. Higher risers provide a better liquid seal to prevent liquid leakage to the next tray, but increase gas flow resistance, resulting in increased tray pressure drop. The diameter of the riser directly affects the gas flux. Larger riser diameter can allow more gas to pass through, reduce gas flow rate, reduce gas entrainment of liquid, but will occupy more tray area, reduce tray utilization; smaller riser diameter will increase gas flow rate, improve gas kinetic energy, conducive to bubble dispersion, but may lead to gas entrainment of liquid phenomenon intensified, affecting the separation effect of the tray. Therefore, it is necessary to consider the height and diameter of the riser tube in order to optimize the operation performance of the bubble tray.

Open porosity and pore size: The open porosity and pore size on the blister directly affect the gas throughput and bubble size. Larger open porosity and pore size can allow more gas to pass through, improve gas flux, and thus increase the processing capacity of bubble tray, but may lead to larger bubbles, shorter gas-liquid contact time, and slightly lower mass transfer efficiency. Smaller open porosity and pore size will limit gas flow rate and reduce the processing capacity of bubble tray, but it can form smaller bubbles, make gas-liquid contact more complete and mass transfer efficiency higher. Therefore, when designing bubble caps, it is necessary to select open porosity and pore diameter reasonably according to specific process requirements and operating conditions to balance the relationship between treatment capacity and mass transfer efficiency.

Slot shape and size: Slot shape (such as triangle, rectangle, trapezoid, etc.) and size have important influence on bubble dispersion effect and gas-liquid contact mode. Different shapes of slots produce different bubble shapes and trajectories. For example, triangular slots can disperse gas into finer bubbles, and bubbles are more easily mixed with liquid in the process of rising, improving mass transfer efficiency.

- Name(chinese)

- Name(English)

- Jiangxi Pingxiang Kelong Petrochemical Equipment Packing Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Jiangxi Pingxiang, China

- Nearby port

- Ningbo,Guangzhou

Pingxiang City Kelong Petrochemical Equipment and Filler Company, Ltd., Jiangxi Province is located in Pingxiang City, which is known as the "Hometown of Filler." The factory is located in Zhuting Industrial Zone, Luxi County, Pingxiang City, 320 Lubian, close to the Pingzhe National Highway, a 15-minute drive from Shanghai-Kunming Expressway, and a 30-minute drive from Gan Mingyueshan Airport. It has convenient transportation location advantages. The company has a registered capital of 80 million yuan, covers an area of 40 acres, has 168 employees and 12 professional and technical personnel. It is a governing unit of the Chemical Technology Center Station of the Ministry of Chemical Industry, a member unit of the China Petroleum and Chemical Survey and Design Association, and a member of Tianjin University and South China University of Technology. One of the few cooperative units. The company has strong technical force and advanced production process equipment, and has a complete ISO9001 certification management system. The various tower internals, metal fillers, plastic fillers, ceramic fillers, chemical equipment and complete sets of equipment, petrochemical parts, molecular sieves, activated alumina, catalysts and other products we produce are sold to coking, environmental protection, chemical fertilizers, chemical industries, refining, smelting, electric power, salt industry, pharmaceutical and other chemical companies across the country, and have self-operated import and export rights. The products are exported to global chemical companies such as Japan, South Korea, Iran, Germany, the United States, and Brazil, with good results. It has been well received by customers. The company has always pursued the goal of putting quality first, winning customers with integrity, and seeking development with innovation. We are willing to sincerely cooperate with domestic and foreign customers for mutual benefit and common development. We welcome new and old customers to come and negotiate business by letter.- Name(chinese)

- Name(English)

- Jiangxi Pingxiang Kelong Petrochemical Equipment Packing Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Jiangxi Pingxiang, China

- Nearby port

- Ningbo,Guangzhou

Pingxiang City Kelong Petrochemical Equipment and Filler Company, Ltd., Jiangxi Province is located in Pingxiang City, which is known as the "Hometown of Filler." The factory is located in Zhuting Industrial Zone, Luxi County, Pingxiang City, 320 Lubian, close to the Pingzhe National Highway, a 15-minute drive from Shanghai-Kunming Expressway, and a 30-minute drive from Gan Mingyueshan Airport. It has convenient transportation location advantages. The company has a registered capital of 80 million yuan, covers an area of 40 acres, has 168 employees and 12 professional and technical personnel. It is a governing unit of the Chemical Technology Center Station of the Ministry of Chemical Industry, a member unit of the China Petroleum and Chemical Survey and Design Association, and a member of Tianjin University and South China University of Technology. One of the few cooperative units. The company has strong technical force and advanced production process equipment, and has a complete ISO9001 certification management system. The various tower internals, metal fillers, plastic fillers, ceramic fillers, chemical equipment and complete sets of equipment, petrochemical parts, molecular sieves, activated alumina, catalysts and other products we produce are sold to coking, environmental protection, chemical fertilizers, chemical industries, refining, smelting, electric power, salt industry, pharmaceutical and other chemical companies across the country, and have self-operated import and export rights. The products are exported to global chemical companies such as Japan, South Korea, Iran, Germany, the United States, and Brazil, with good results. It has been well received by customers. The company has always pursued the goal of putting quality first, winning customers with integrity, and seeking development with innovation. We are willing to sincerely cooperate with domestic and foreign customers for mutual benefit and common development. We welcome new and old customers to come and negotiate business by letter. -

Send your message to this supplier*From:*To:

Ms. liang xiao

*Message:

Ms. liang xiao

*Message:Inquiry

Copyright © 2003 - 2026 Goepe.com All rights reserved.